|

||||||||||||||||||||||||||||||||

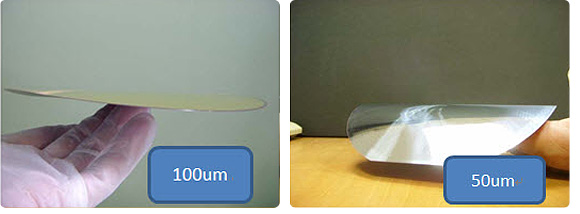

Advantage of our products: 1. Metal film Wafers, such as Al, Ni, Ag, Au, Ti, Pt, wafers, platted with 99.99% + or 99.995% +, plasma. 2. 100% pass peeling test before delivery. No peeling problem. Application: 1. Packaging test. 2. Lapping test. 3. Cutting test. 4. Wafer mounting test. 5. Wire bonding test. 6.Quality control of the machine / Setting of parameter test. 7. Special experiment/ proofing 8. Dummy IC/chips producing |

|

|||||||||||||||||||||||||||||||

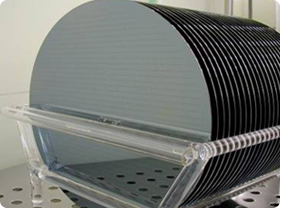

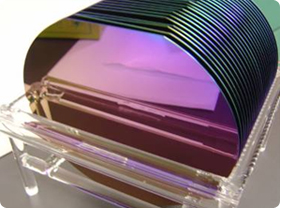

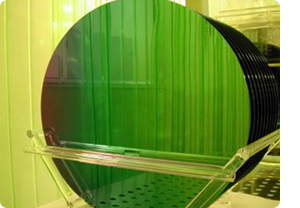

Thermal Oxide wafer

Thermal Oxide waferApplication: 1. Etch rate test. 2. Metal bonding test 3. Electric insulation layer |

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|